Wow, has this class been a whirlwind or what. This assignment has at times been incredibly frustrating and stressful especially during the model generation. Even so I still have thoroughly enjoyed myself and not just because i got to create something Harry Potter based. I did not expect my final model to end up looking the way its does. In the beginning I was adamant that I was going to mostly laser cut and made from plywood. I realise now that that was quite narrow-minded.

My conceptual MP3 player has gone through many developments and iterations to get to the final product. The things I have learnt through this process both good and bad and helpful and difficult shall be useful knowledge for future work.

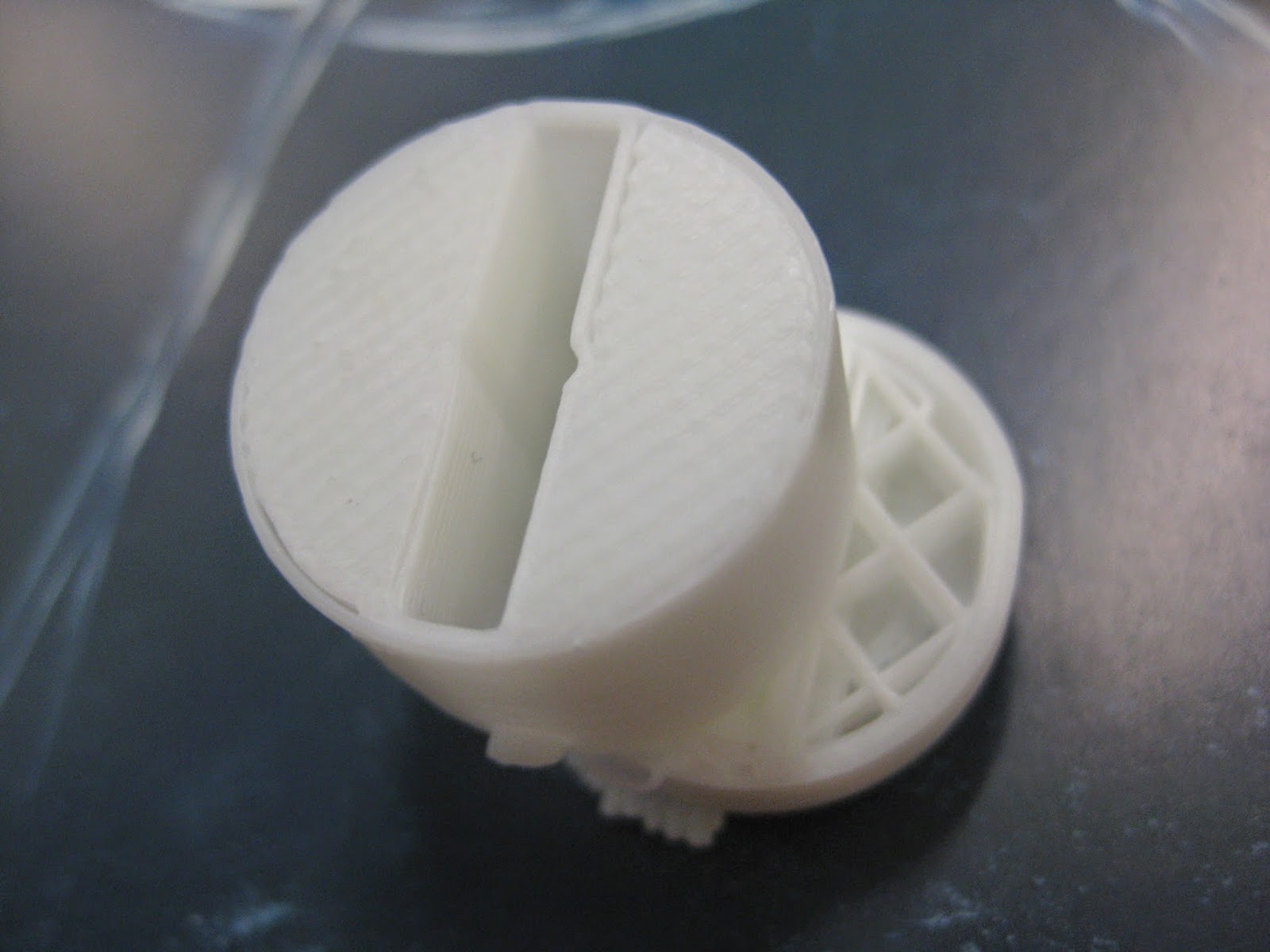

Each week there has been a development in my design due to either a failure of the previous model, such as my first base sphere getting the LED stuck in the battery slot, which has had to be rethought and altered to generate a more effective solution, or a suddenly more brilliant idea that would enhance my design and make it better, such as the rastering of a pattern onto the surface of Deathly Hallows sign.

All in all it has been a success and I am happy with the work I have produced for this Assignment and my final conceptual MP3 player model. If I could go back do some things differently I would probably do more material exploration at the beginning to figure out all the options I had to work with. I would also try and manage my time more wisely so I was more on top of the work and having models prepared for class each week. But as far as my designing and generating goes I can't think of anything I would do differently. I am happy with the process I followed and what I accomplished.

All in all it has been a success and I am happy with the work I have produced for this Assignment and my final conceptual MP3 player model. If I could go back do some things differently I would probably do more material exploration at the beginning to figure out all the options I had to work with. I would also try and manage my time more wisely so I was more on top of the work and having models prepared for class each week. But as far as my designing and generating goes I can't think of anything I would do differently. I am happy with the process I followed and what I accomplished.